FURNACE BRAZING

Overview

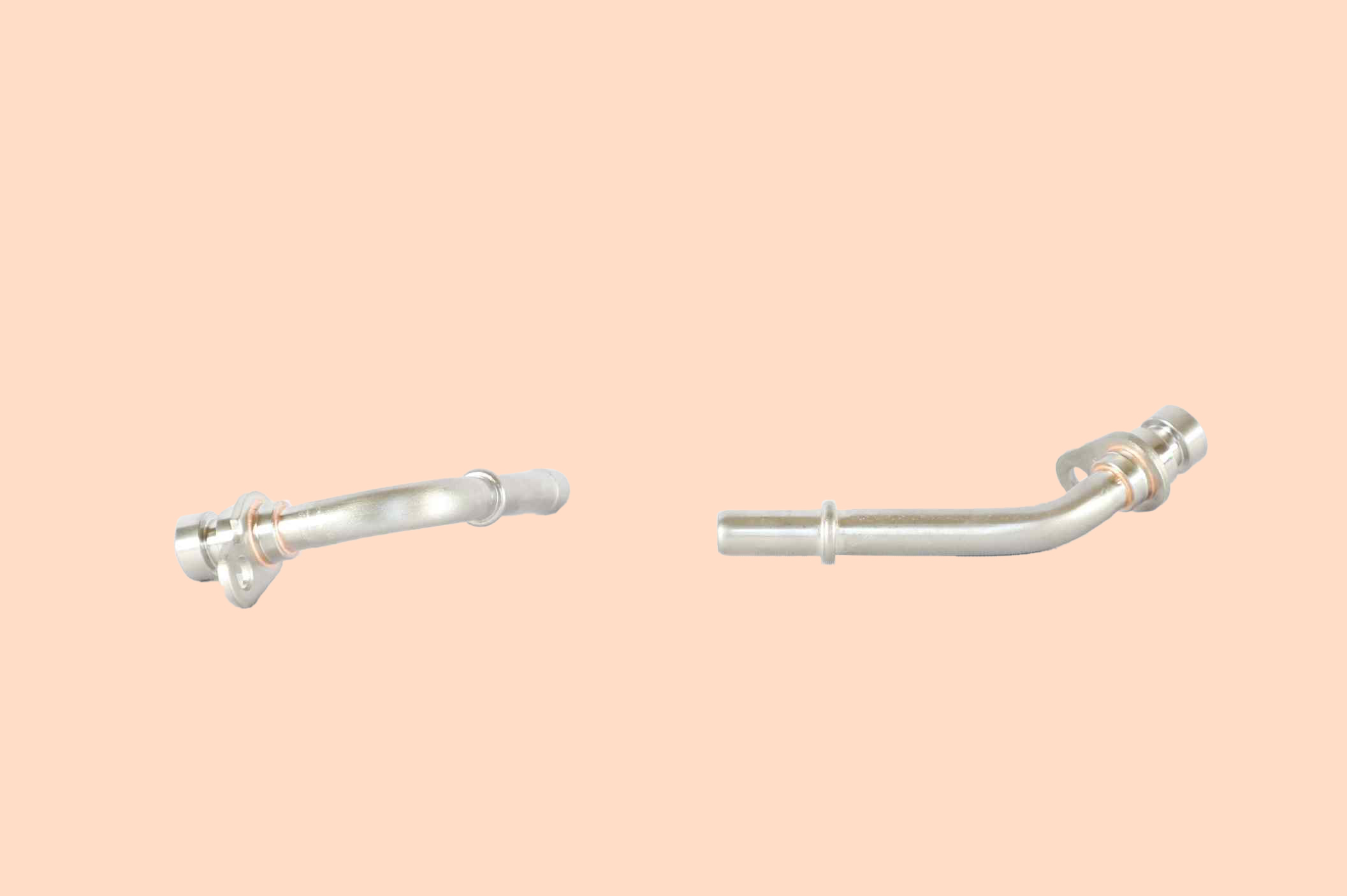

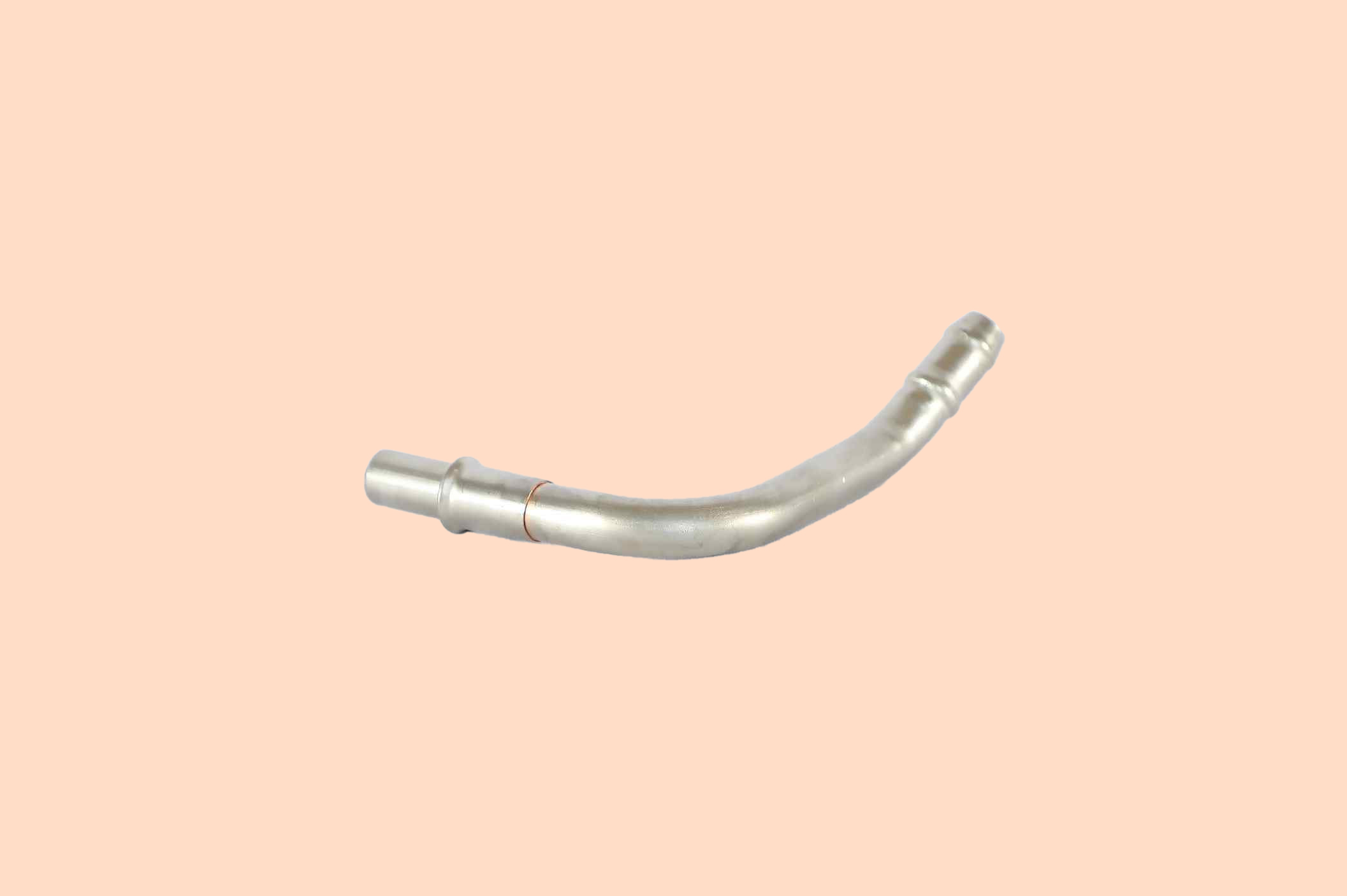

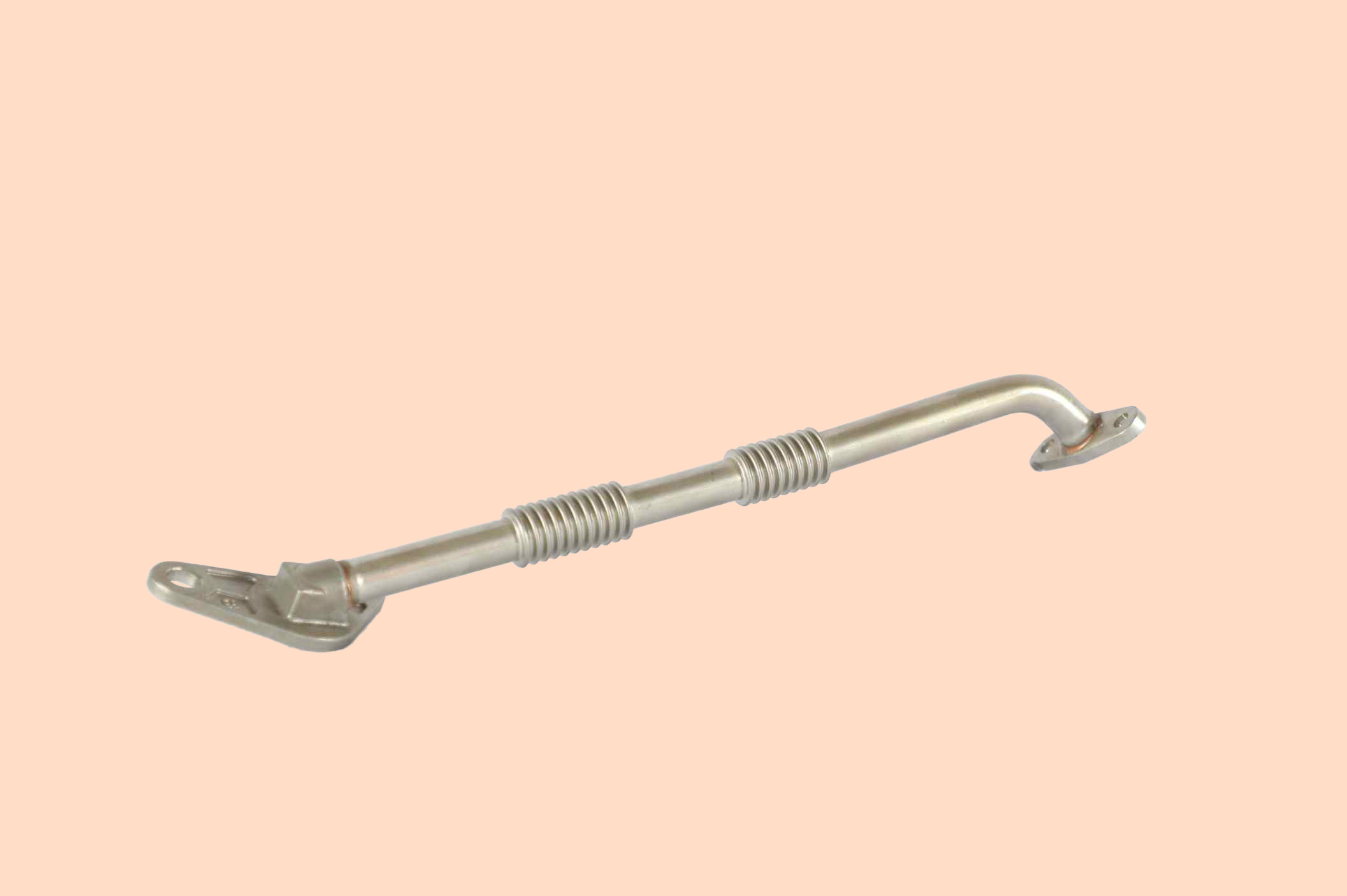

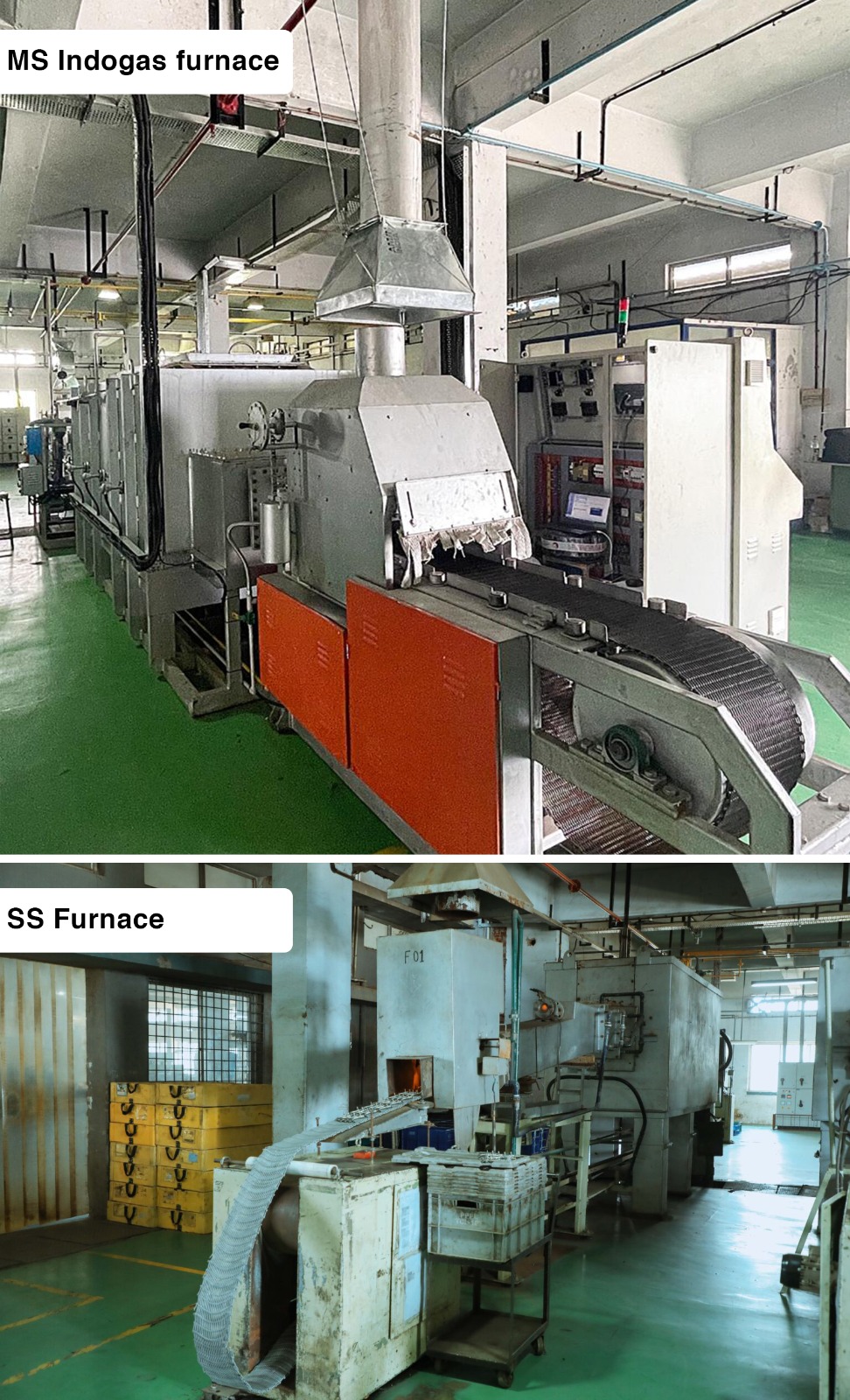

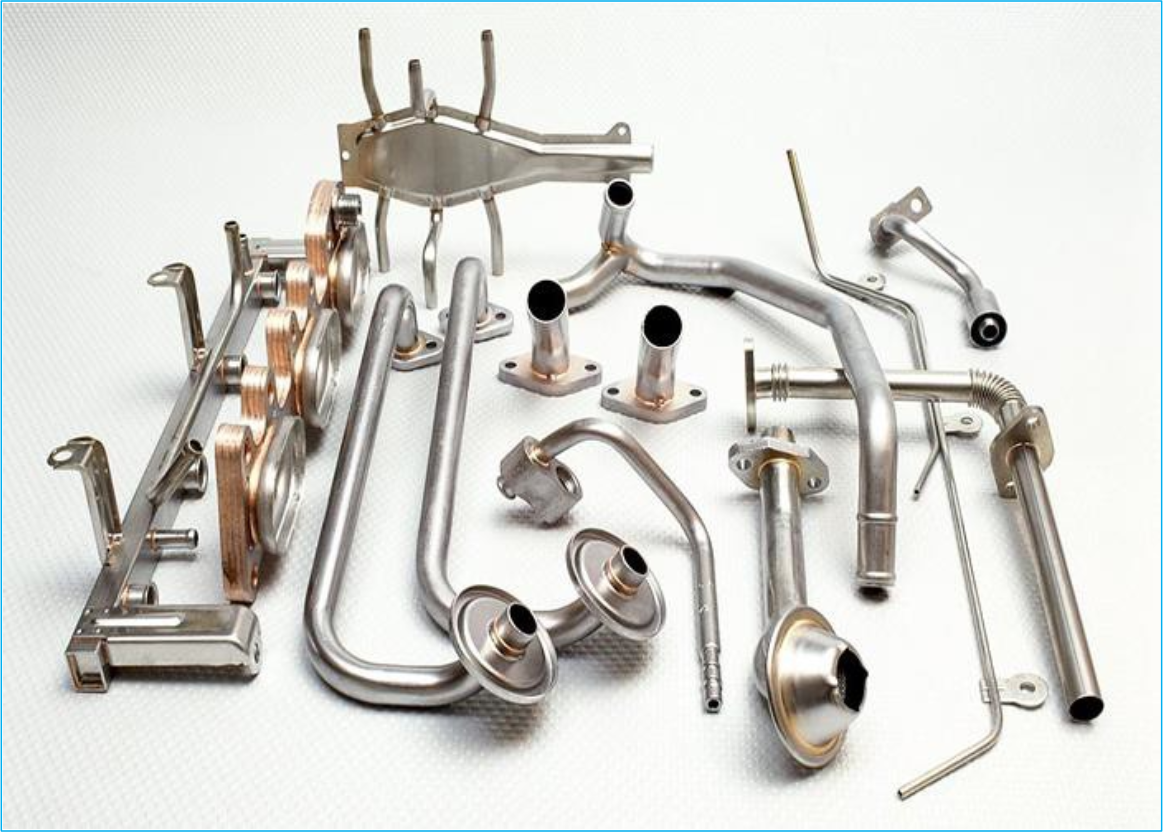

Our inert atmosphere brazing facility with high-temperature capabilities, provides the production of critical components used in industries such as aerospace, automotive, and electronics. The precision, strength, and reliability are our trademarks.

Having an inert atmosphere brazing facility with a brazing temperature above 800°C up to 1140°C allows for the brazing of a wide range of materials, including stainless steel, carbon steel, copper, and alloys. This facility is ideal for producing critical components that require high strength, tight tolerances, and excellent corrosion resistance.

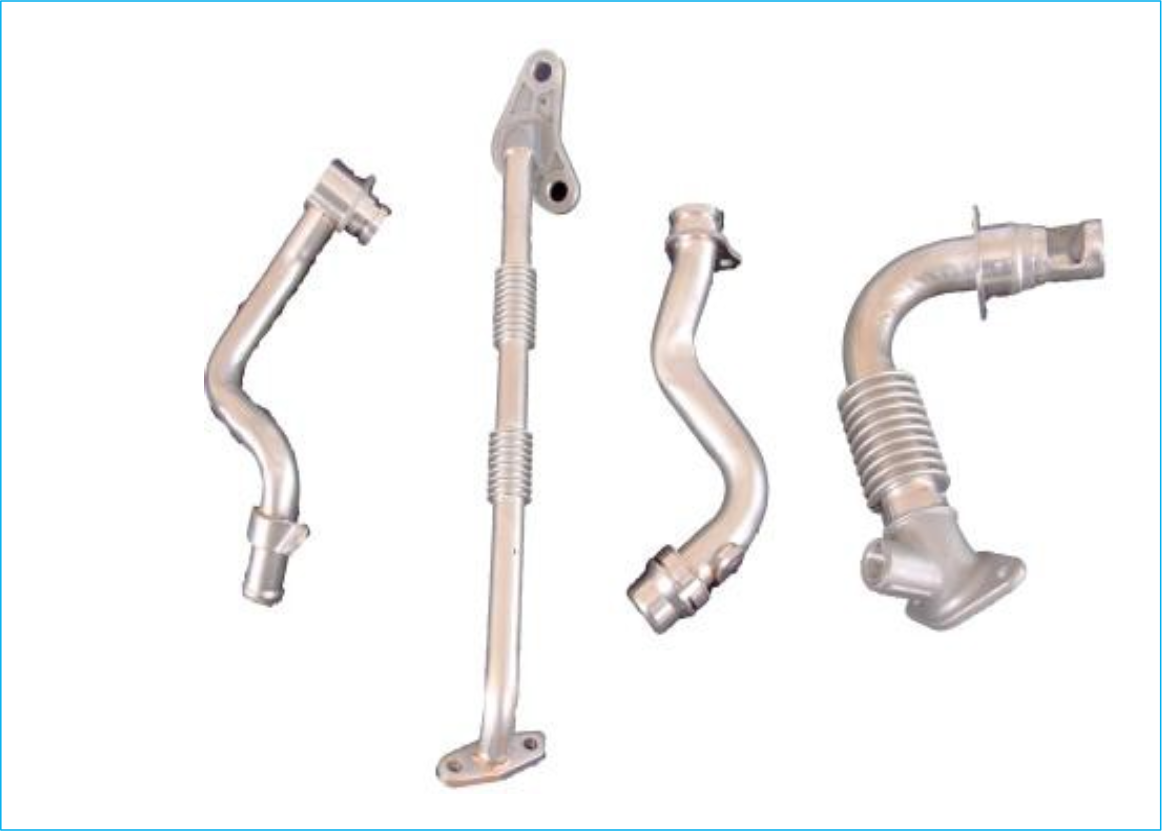

The process takes place in a controlled atmosphere to prevent oxidation and achieve clean, strong joints. Inert atmosphere brazing, as the name suggests, uses gases like nitrogen or argon to create a non-reactive environment, ensuring minimal oxidation and high-quality brazed joints.

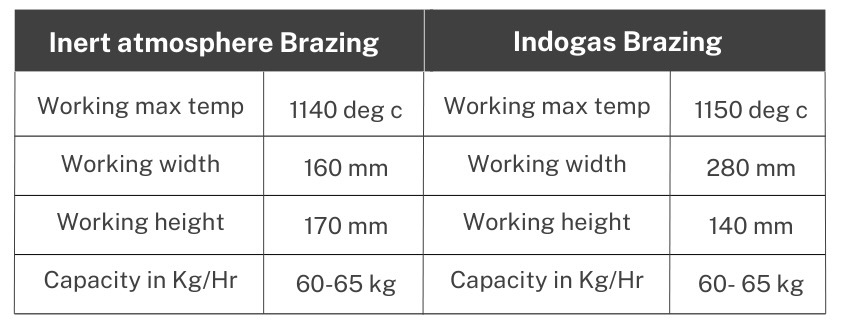

Inert atmosphere brazing

Best quality of brazing joint

Brazing process in controlled atmosphere

Suitable for large volume of production

Continuous conveyor type brazing process runs 24/7

No use of flux

Flux not needed for brazing which ensures clean and bright parts as compared to any other type of brazing

Consistency

Strict process control ensured by every hour monitoring of important process parameters.

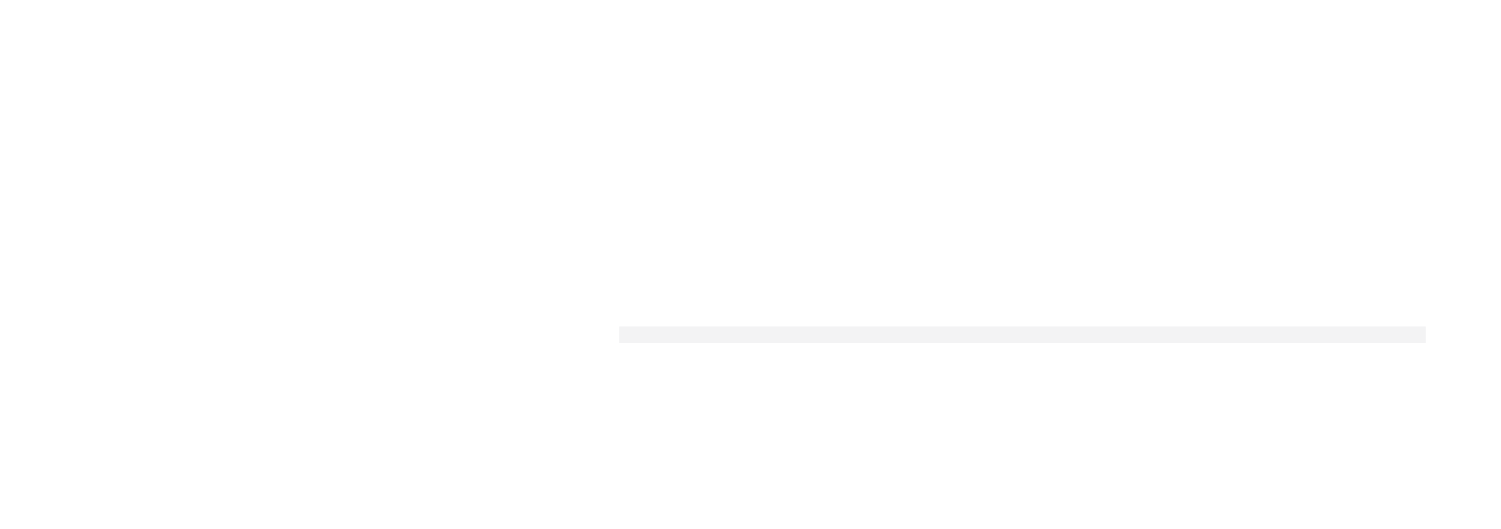

Indogas Brazing Furnace