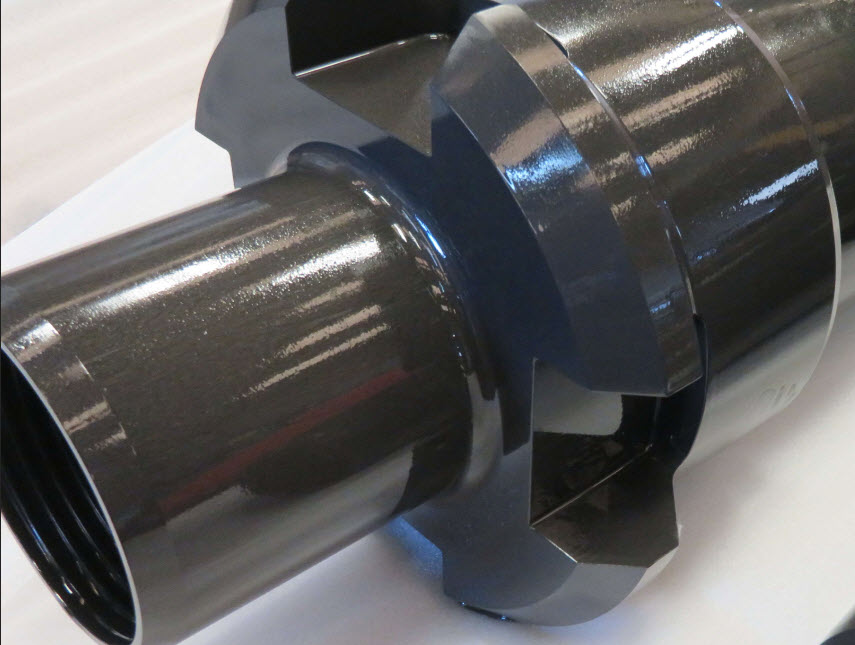

Phosphating plays a vital role in enhancing the overall quality and performance of steel and iron components, making it a critical step in ensuring their reliability and longevity in demanding environments.

It is a surface treatment process normally done for surface preparation before the powder coating, CED coating, rubber bonding process, etc. Zinc phosphating, in particular, enhances lubricity and serves as a base for paints, oils, and waxes. While naturally a dark grey, zinc phosphating can be dyed for a matte black appearance, offering versatility in aesthetic finishes.

Zinc Phosphating is highly favoured for protecting ferrous metals against corrosion, particularly in harsh weather conditions, making it a top choice in the automotive sector.

Phosphating provides rust prevention too. It forms a durable barrier against corrosion, enhancing the overall longevity and performance of the treated components.

Phosphating is favoured for its ability to improve paint adhesion and provide a more uniform surface for subsequent coatings.

This process is widely used in various industries, including automotive, aerospace, and manufacturing, where the longevity and durability of metal components are paramount.

Founded with a commitment to quality and innovation, our company stands as a leading manufacturer of a wide range of products. We have expertise from PTFE Seals & Rubber Oil Seals. We also manufacture Screen Filters, Connectors, Wear Sleeves, Oil Level Gauges (DIPSTICKS), Hardened Washers, Brackets, and many other Diesel Engine Parts.