OIL SEALS – PTFE & RUBBER

Overview

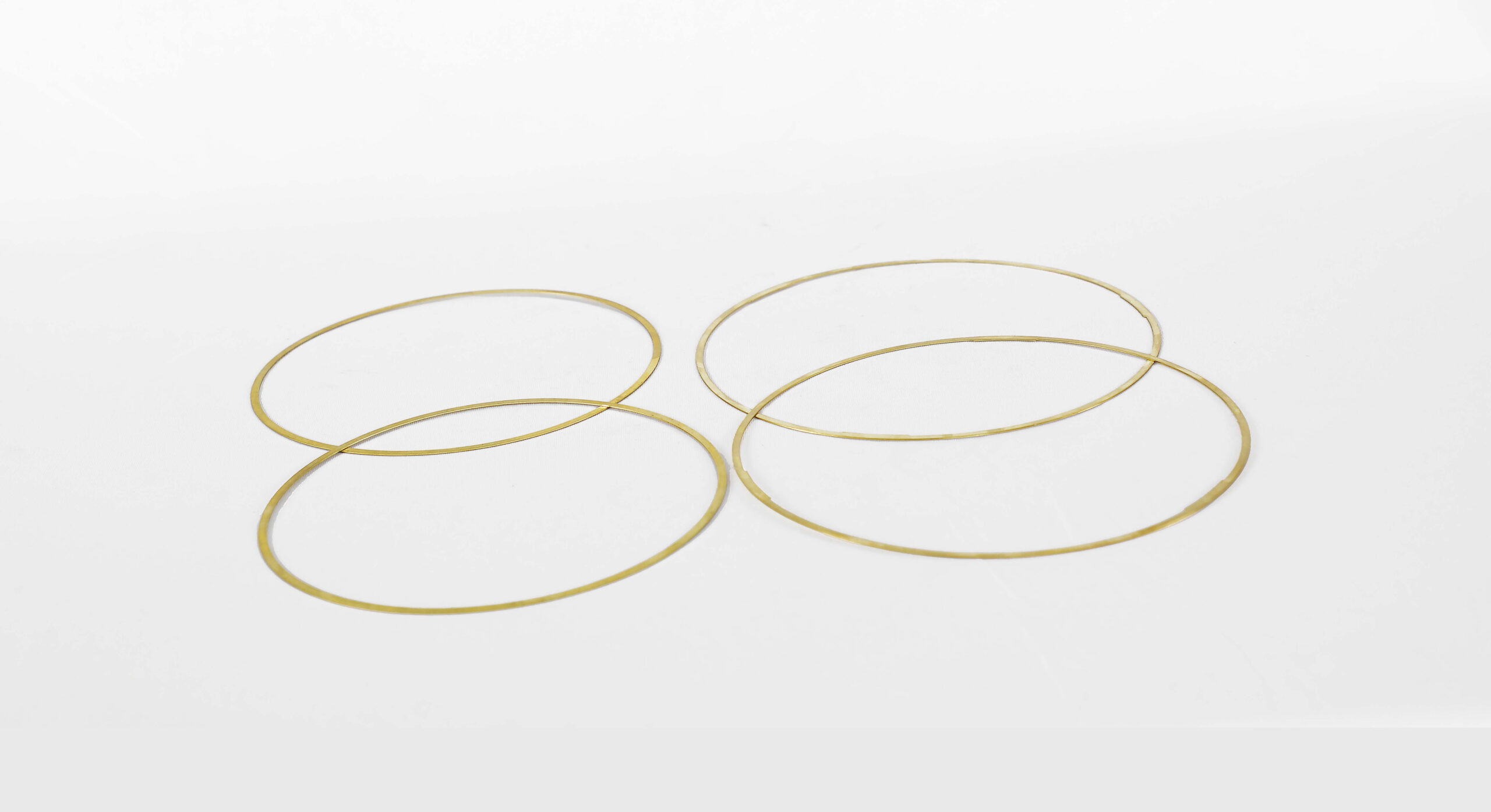

PTFE OIL SEALS

PTFE oil seals have to perform in extreme conditions. Therefore, we accommodate all relevant conditions to maintain the integrity of the rubber oil seal in these circumstances. Our standard and custom rubber oil seals can match the increasingly demanding applications of any industry.

Dry Running

Suitable for dry running & poorly lubricated

conditions. They can survive extended

periods of lubricant starvation without

detriment to the seal or shaft surface

Low Shaft Wear

PTFE Oil seals employ a “lay-down” lip sealing

mechanism & therefore have a wider contact

band on the shaft than conventional seals which reduces contact pressure on the shaft &

reduces wear rate.

Endurance

Extended service life is significant advantage of PTFE seals over conventional Seals.

Withstands wide temperature range

Filled PTFE can withstand at wide temperature range -100°C to +260°C. The exceptional low temperature capability of PTFE seals makes them ideally suited to automotive & aerospace applications.

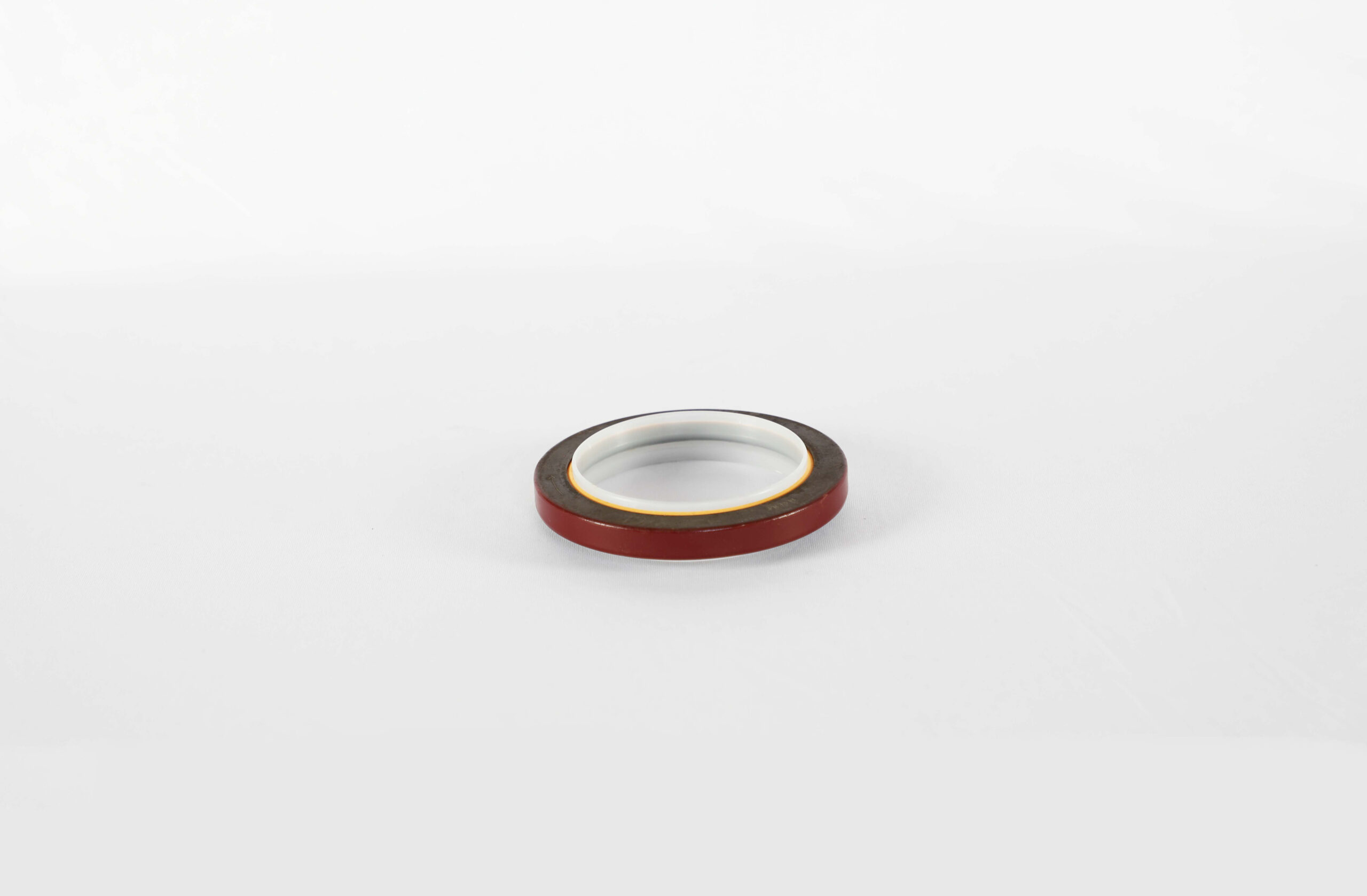

RUBBER OIL SEALS

Dry Running

Suitable for dry running & poorly lubricated

conditions. They can survive extended

periods of lubricant starvation without

detriment to the seal or shaft surface

Low Shaft Wear

PTFE Oil seals employ a “lay-down” lip sealing

mechanism & therefore have a wider contact

band on the shaft than conventional seals which reduces contact pressure on the shaft &

reduces wear rate.

Endurance

Extended service life is significant advantage of PTFE seals over conventional Seals.

Withstands wide temperature range

Filled PTFE can withstand at wide temperature range -100oC to +260oC. The exceptional low temperature capability of PTFE seals makes them ideally suited to automotive & aerospace applications.